Shape Design of Banking Dies

In a blanking die, the material that is blanked out passes through the die and falls down. This part (the die cross section) is composed of a cutting edge section, a land part (also called a parallel part), and a relief part (also called the second part). While the land part is prepared foreseeing a margin for re-grinding, the following problems occur if this is made too long.

| 1. | The side surface wear to the land part becomes severe and it becomes easy for burrs to appear. |

| 2. | Bending of the blanked and dropped product becomes large. |

| 3. | During hole punching, the pressure for pushing down the punching chaff becomes large increasing the load on the punch (causes breakage of the punch). |

| 4. | Scraping and seizing can occur and can easily cause clogging |

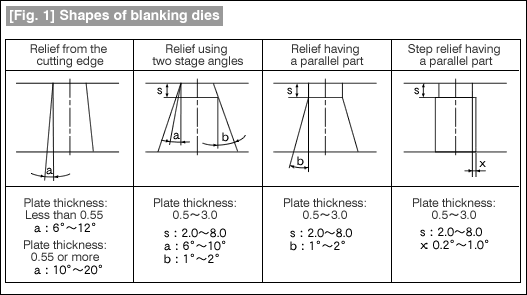

Figure 1 shows the side surface shapes of the blanking dies.

Explanation of Blanking Die Shape

(1) Relief from the cutting edge

This is used very frequently at the time of forming the die using wire electric discharge machining. The cost of production will be low. Considering the widening of the die due to re-grinding, a smaller clearance is used.

(2) Relief using two stage angles

Although this is a tedious shape to manufacture, this is an ideal shape because there is no difficulty in the passage of blanked material. This is used very frequently in precision dies in order to form thin plate materials.

(3) Relief with a parallel part

This can be said to be the standard type of die shape. This is used frequently in dies for small to large production quantities of ordinary products. For small production quantities, the use of the "relief from cutting edge" is most common.

(4) Step relief

This is very frequently used in the case of small shapes such as hole punching, etc. If the step relief is made halfway (about twice the round hole diameter) it makes clogging occur easily. It is better to make the step difference either very small or very large

WHAT WE SPECIALIZING ARE PUNCHES ,DIES,PINS ,BUSHES AND PRECISION ROUND PARTS

1.Standard punches.Punches DIN 9861,Punches ISO 8020,Ejector punches,Shoulder punches,Polit punches,Block punches

2.Punches and Dies as Standard DAYTON / MISUMI / FIBRO

3.Standard Pins,Ejector pins DIN 1530 A/ DIN 1530 AH/ DIN 1530AP Black nitride/ Step Ejector pins. Flat Ejector DIN 1530 F/ Ejector Sleeve DIN 16756

4.Standard Bush DIN 172 / DIN 179 Standard Die Bush ISO 8977 / DIN 9845

5.Carbide punches,pins,bushes

6.Precision parts as per drawings