Accuracy Judgment of Press Dies

In general the dimensional accuracy or the shape accuracy of the product is used as a "measure" of die accuracy. Products that require very strict tolerances, for example, lead frames or IC connectors, etc., are products that require very high accuracy, and dies for producing these are recognized as high accuracy dies. This is a point that no body questions.

Now let us consider where this high accuracy is found in such dies. Since the shapes of punches and dies are transferred to the products, the shapes of punches and dies are produced with high accuracy using multiple cutting and other methods employing profile grinding machining (PG machining) or wire electric discharge machining (W/EDM). Definitely one factor in judging die accuracy is the preparation of the shapes of punches and dies corresponding to the dimensional tolerances of the product.

The preparation of the shapes of punches and dies may also be necessary for maintaining clearances. As the material plate thickness of products becomes smaller, the removal clearance also becomes proportionately smaller. It is very difficult to maintain this uniformly. Therefore, even if the tolerance of the shape and dimensions of the product are large, because small clearances have to be maintained in the case of forming products from thin plates, it is necessary to maintain high accuracy when preparing punches and dies and the assembling position inside the die. It is also possible to say that even the plate material thickness is a "measure" for evaluating the accuracy of the die. Even the accuracy of the shape of products becomes bad with a small change in the mating if the plate thickness of the material becomes small. Of course, the preparation of the shapes of punches and dies becomes important.

Through the preparation of the shapes of the punches and dies, it is possible to obtain satisfactory parts. Since punches and dies are placed as a top die and bottom die, even the guide posts and bushes (guides) that determine the accuracy of the relationship between the top die and the bottom die have very important indirect roles in the die accuracy. Considering that a punch is made into a punch guide using a stripper, this is also related to the preparation of the stripper (inner guide), the stripper bolt, spring, etc.

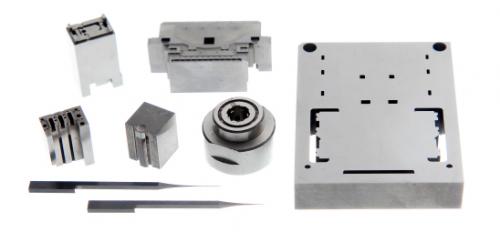

WHAT WE SPECIALIZING ARE PUNCHES ,DIES,PINS ,BUSHES AND PRECISION ROUND PARTS

1.Standard punches.Punches DIN 9861,Punches ISO 8020,Ejector punches,Shoulder punches,Polit punches,Block punches

2.Punches and Dies as Standard DAYTON / MISUMI / FIBRO

3.Standard Pins,Ejector pins DIN 1530 A/ DIN 1530 AH/ DIN 1530AP Black nitride/ Step Ejector pins. Flat Ejector DIN 1530 F/ Ejector Sleeve DIN 16756

4.Standard Bush DIN 172 / DIN 179 Standard Die Bush ISO 8977 / DIN 9845

5.Carbide punches,pins,bushes

6.Precision parts as per drawings